Field service work often involves going to extremes — repairing wind turbines hundreds of feet off the ground, diving in freezing water for boat maintenance, or traveling to some of the most remote locations on earth — but some jobs are simply too dangerous for human techs.

When the 2011 Tōhoku earthquake triggered a tsunami that left the Fukushima Daiichi nuclear power station in ruins, the plant’s operator, Tokyo Electric Power Co., was faced with the challenge of decommissioning the plant. Unfortunately, high radiation levels have made manual cleanup of the hazardous nuclear fuel nearly impossible.

Robots to the Rescue

The solution to this extreme field service predicament? Robots. Major companies including Hitachi, Toshiba, Mitsubishi, BMW, and iRobot have developed custom robots that can remove debris, climb stairs, float, or swim through irradiated water, and crawl through pipes and other hard-to-reach places to measure radiation levels. But the radiation has created high heat levels that have melted the internal wiring of many of these robots, destroying them before they can complete their work.

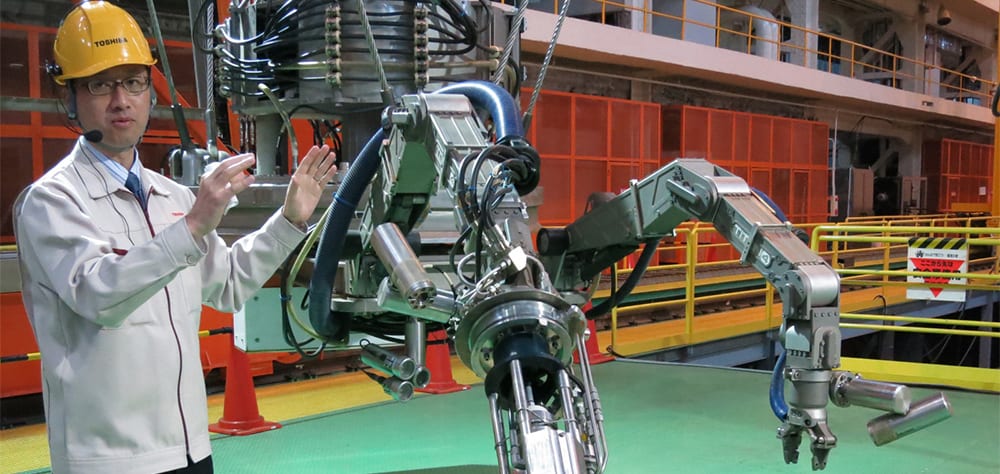

The cleanup effort needed a more hardcore ‘bot, and Toshiba thinks it has the answer: an amphibious robot that will remove debris along with 566 fuel-rod assemblies from the spent fuel pool in the number 3 reactor — an area of the plant that has particularly high levels of radiation.

This robot is actually made out of two massive remote-controlled rigs that are more than two stories high and wider than a school bus. Its two pincer arms can dexterously grab and cut debris, and place it in a radiation-proof storage container. The robot’s huge crane, which alone weighs about 90 tons, will lift the storage container out of the building for transportation to a temporary storage site.

Preparing with Virtual Reality

The cleanup process at Fukushima is projected to take 30 to 40 years, and robots will continue to be an integral part of this work.

“The personnel exposure to radiation would be much higher without robots, and off-site releases would be much higher,” Lake Barrett, a nuclear energy expert who has consulted on the decommissioning program, told the LA Times.

In addition to robots, workers are also using virtual reality to help practice the cleanup tasks they will complete once reactor buildings are safe to enter. Worker are immersed in a 3-D virtual environment based on the plant’s original designs and on-site data gathered by robots. These innovative technologies will play a big role in the future of field service, transforming how technicians do their jobs by helping them safely complete dangerous tasks.

Share this: